Photo: Deutsches Museum | Christian Illing

Materials, Energy, Production

Ceramics – Made from Earth

Thousands of years ago, people formed vessels and works of art from clay minerals found in the ground. Today, alongside their continued use in objects of art, we also find ceramics as a material in technology and industry.

What are Ceramics?

Ceramics are among the earliest evidence of human civilisation. The first vessels were used by people over 10,000 years ago for cooking and to store food. The raw material for their production was clay, which could be found almost everywhere. By the beginning of the modern era, ceramics were therefore common in almost all parts of the world. Today, the term “ceramics” covers a wide range of non-metallic, inorganic materials that are first shaped and then fired during manufacture. These include classic pottery (earthenware), stoneware and porcelain, as well as high-tech ceramics developed for technological applications. The exhibition is divided into five areas that present the subject from different perspectives.

15,000 Years OldAge of the oldest ceramic vessels found to date

380,000 VoltsVoltage that a ceramic insulator must be able to withstand

1,600°CTemperature reached by ceramic heat insulators in space probes during reentry into the atmosphere

Exhibition Themes

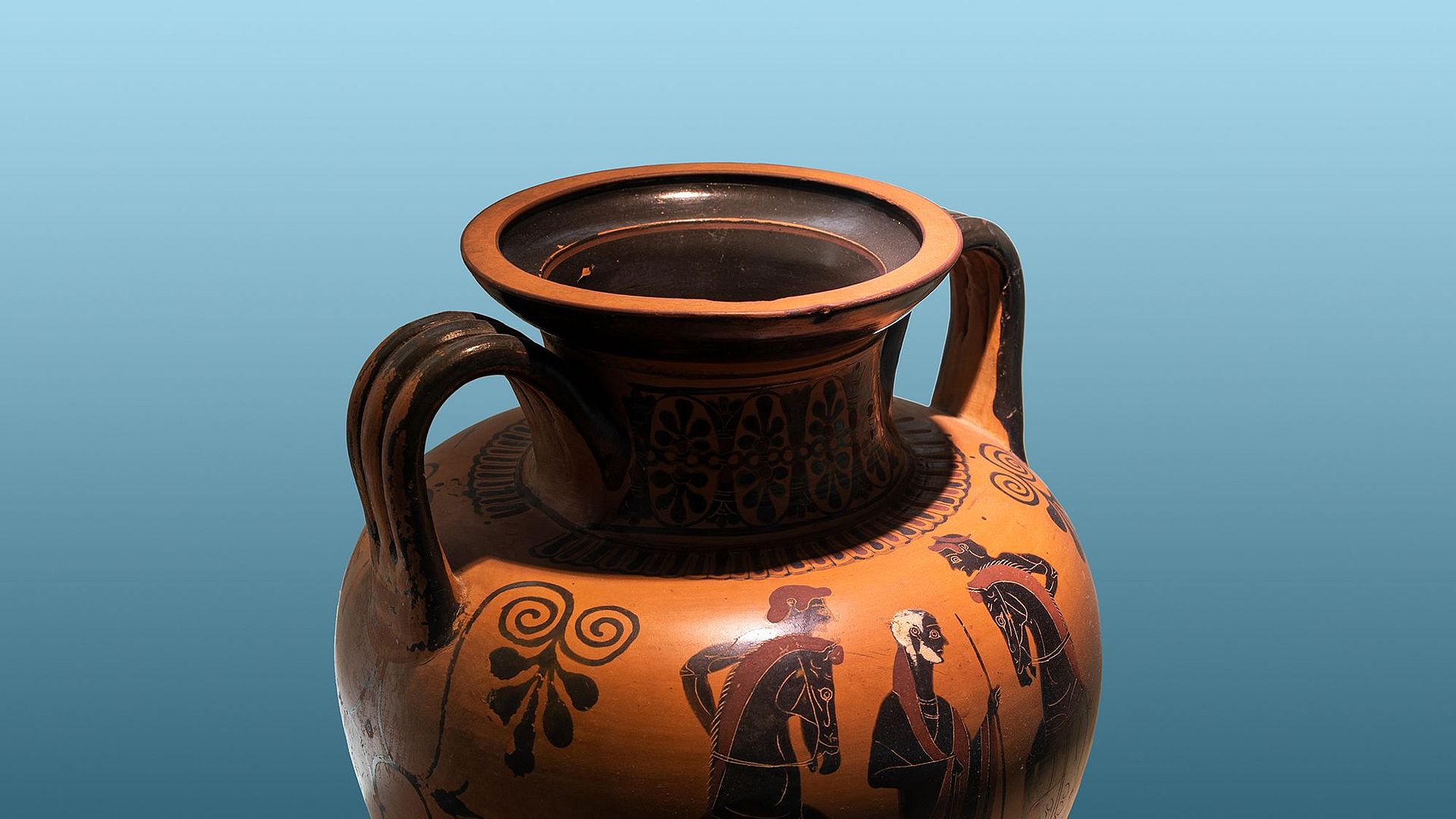

Clay minerals, the raw material for ceramics, can be found almost everywhere in the world. People have been processing this raw material for thousands of years to make objects of art and storage vessels – some of which are impressive in size. Photo: Deutsches Museum | Christian Illing

Ceramics in the Ancient World

An ensemble of large ancient ceramic objects, including storage and transport vessels of impressive size, as well as bricks and clay pipes, illustrate the diversity of early ceramic production. The techniques used in Greek black and red figure vase painting are presented using original objects from antiquity. The exhibition also looks at the spread of ceramic products around the world.

Making ceramics has always been about combining functionality and art. This photo shows an Art Nouveau vase from 1900. Photo: Deutsches Museum | Christian Illing

Ceramics and Art

Mankind’s need for artistic expression is clearly evident in the numerous everyday objects made from ceramics. The exhibition spans from the earliest artistic artefacts – such as cult figurines made from ceramics – to elaborately crafted historical stoneware jugs and decorative porcelain, as well as more recent objects where the artist emerges from anonymity.

The range of applications for ceramics is extraordinarily diverse. The Technical Ceramics area of the exhibition presents developments that lead to the creation of modern ceramics. Photo: Deutsches Museum | Christian Illing

Technical Ceramics

Stoneware initially found widespread use from the High Middle Ages in the form of cups and jugs. From 1710, porcelain was also produced in Europe; it was not only a coveted object of royal collections, but has also been used in insulators since the beginning of electrification. For the chemical industry that emerged after 1850, ceramics became indispensable thanks to their resistance to acid. Researchers are constantly developing new ceramic materials for a wide range of technological applications. This is illustrated by examples seen in household and automotive technology, in medicine and in environmental and energy technology. The importance of refractory ceramics in industry is demonstrated in the production of steel and other applications.

Von der Töpferscheibe bis zum Brennofen: Die Herstellung der Keramik. Photo: Deutsches Museum | Christian Illing

Manufacturing Processes

This part of the exhibition is devoted to the most important steps in the production of ceramics – from preparation of the raw materials to their shaping and firing. Shaping by hand on the potter’s wheel and the use of industrial presses can be seen on display. The various intermediate stages carried out in the production of porcelain tableware can also be studied here.

Inside the Ceramics Exhibition

Mini-Brick Production Plant

This model production plant is a fully automated brick-making facility. The soft clay is pressed by means of a vacuum extruder and an auger through a die to form a strand, which is then cut into individual bricks. After the drying process, the bricks are fired in the kiln at around 800°C for about four hours. For a small donation, you can take home one of the freshly fired mini bricks in 60 x 45 x 28mm format. The film is currently only available in German.

Activities

During the mini-brick-making demonstration, you can see how small bricks are formed and fired in a fully automatic process. Photo: Deutsches Museum

Brick Production

In the final room of the exhibition, visitors can see bricks from 4,000 BC right up to the present day. There are clear explanations about the function of roof tiles and how they have always been used in the ornamentation and decoration of a building. Visitors can also watch a mini-brick model plant in action to learn more about how bricks are industrially manufactured. Plastic clay is placed into a box feeder and formed into perforated bricks. After drying for 20 hours, they are then fired in a continuous kiln at approximately 850°C for a firing cycle time of around four hours.

For a small donation, you can take one of the freshly fired mini bricks home with you!

Any Questions?

![Porträt einer Frau in Business-Kleidung: hellblondes Haar zurückgesteckt, blaues Hemd mit offenem Kragen unter einem dunkelblauen Blazer, sichtbare Perlenohrringe, neutraler hellgrauer Hintergrund.]()

Dr. Marcelina Malissek

Curator

Materials DepartmentDeutsches Museum

80306 MunichTelephone +49 89 2179 640

Fax +49 89 2179 513

Email m.malissek@deutsches-museum.de

Do you have organizational questions?

Cornelia Schubert

Assistance to department heads, main department heads and curators

Susanne Schmölz

Assistance to department heads, main department heads and curators